Close up of the control panel (in the storage position).Note the pump on the left mounted to the bracket. This would be moved in later designs because of the heat on the mash tun.

Problems and Revisions

To HOT!

After building the brewery, several problems became apparent. First off, the pump for recirculating the mash liquor was perilously close to the mash burner and it was getting hot. It got moved down to where the propane controls are. Also, a large amount of heat rolled up the slant of the mash tun and over the end of the mash tun. To keep this from melting the wires to the grain mill and the tube to the recirculation manifold, I placed a sheet of metal at the end to act as a heat shield.

|

Close up of the control panel (in the storage position).Note the pump on the left mounted to the bracket. This would be moved in later designs because of the heat on the mash tun. |

|

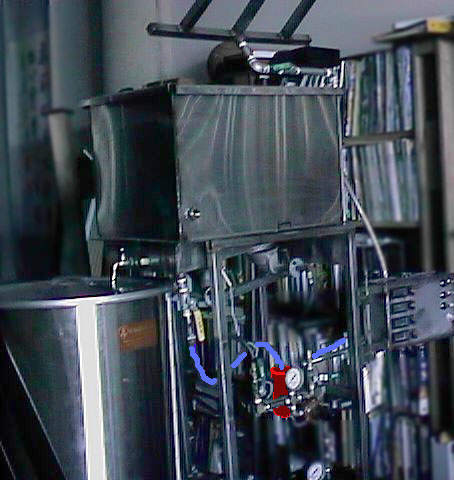

Later picture of the brewery. This time you can see the pump moved from the heat source. I colored the tubing to the pump blue and the pump itself red to make it easier to make out. The first rendition of the sparge manifold is visible also. Control panel is in the operating position. You can also see the placement of the dual propane elements under the mash. |

Go Back to Burner-

Boil Kettle ![]() |

| ![]() Go on to Making the stand portable

Go on to Making the stand portable

| Overview | The Mash Tun | Brewery stand | Hot Liquor Tank | Boil Kettle, Hopback and Cooling |

| Control Panel | Computer Control and data acquisition | Grain Mill | Draught Beer Cooler | HOME |